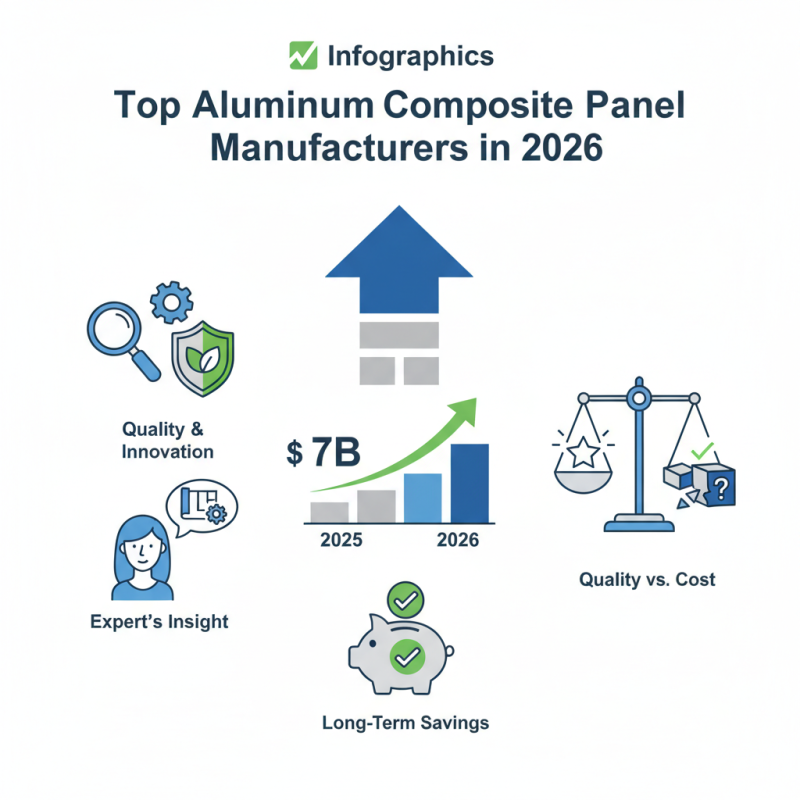

The aluminum composite panel industry is evolving rapidly. In 2026, identifying the best aluminum composite panel manufacturers will be crucial. Various reports suggest that this market will grow significantly, driven by rising demand in construction and architecture. By 2025, the global market is expected to reach USD 7 billion.

Experts like Dr. Jane Smith, a leading authority on architectural materials, emphasize, “Quality and innovation are key in selecting aluminum composite panel manufacturers.” Her insights reflect a growing concern in the industry about product durability and aesthetic appeal. As we analyze manufacturers, we must consider their reputation for quality and customer satisfaction.

Notably, not all manufacturers meet rigorous standards. Companies often struggle to balance cost with quality. This could lead to subpar products in the market. As buyers, we must remain vigilant and informed. Understanding which manufacturers consistently deliver high-quality aluminum composite panels will save significant costs in the long run.

Aluminum composite panels (ACPs) are gaining traction in construction and design. They consist of two thin layers of aluminum enclosing a non-aluminum core. This structure offers strength and lightweight properties, making them ideal for various applications. According to a recent industry report, the demand for ACPs is projected to grow by 4.5% annually through 2026.

These panels are widely used in facades, signage, and interior applications due to their aesthetic appeal and durability. They resist weathering and corrosion, providing longevity. Additionally, ACPs are easy to maintain; a simple wash keeps them looking new. Industry experts indicate that architects favor them for innovative designs and versatility in colors and finishes.

Tip: Always check the panel's fire rating before making a purchase. Fire safety standards vary by region, making this an essential factor.

Despite their advantages, ACPs can pose challenges. Installation requires skilled labor, and improper handling can lead to damage. Additionally, environmental concerns regarding their core materials have sparked debate. Contractors should weigh these factors carefully.

Tip: Research local regulations on building materials to ensure compliance. Staying informed can save time and resources.

When evaluating aluminum composite panel manufacturers, several key criteria emerge as critical. Quality is paramount. High-quality panels possess better resistance to weather and corrosion. According to industry reports, panels with higher aluminum content offer superior durability. Each manufacturer’s material specifications should align with your project’s needs.

Cost is another important factor. Prices can vary significantly. Some manufacturers may offer low initial quotes, but consider long-term performance and maintenance costs. Understanding the total cost of ownership is essential for budget-conscious projects. Additionally, check for certifications. Many panels should comply with fire safety and environmental standards.

Tip: Always ask for samples. This allows you to assess the finish and feel of the panels.

Customer service cannot be overlooked. Responsive support helps during unforeseen challenges. Poor communication can lead to misunderstandings or project delays. Gather insights from past clients about their experiences.

Tip: Read reviews and testimonials. They reveal unfiltered truths about the manufacturers.

Another growing consideration is sustainability. Many manufacturers now focus on eco-friendly materials. Assess the recycling processes they use. Ultimately, selecting the best manufacturer requires thorough research and reflection.

As we look ahead to 2026, the demand for aluminum composite panels continues to grow. These panels are known for their lightweight, durability, and aesthetic appeal. Many manufacturers are stepping up to meet this demand, offering innovative products that cater to diverse architectural needs. However, not all manufacturers are created equal.

In 2026, industry experts suggest keeping an eye on manufacturers that emphasize sustainability. Eco-friendly practices are becoming essential. Some companies are exploring recyclable materials, while others commit to reducing their carbon footprint. This shift reflects a broader trend towards responsible manufacturing. Nevertheless, potential buyers should seek transparency about these claims. It remains crucial to investigate the sustainability practices behind their products.

Additionally, design versatility is a key factor. Many manufacturers now provide a variety of finishes and colors. This allows architects and designers to unleash their creativity. However, the challenge lies in ensuring that these cosmetic options do not compromise the panels' functionality. Not every manufacturer will get this right. Attention to engineering details is vital. Some companies may excel in aesthetics but falter in quality. It’s important to evaluate products thoroughly. Engaging in discussions with industry professionals can provide insights that help navigate these choices.

Aluminum composite panels (ACP) are evolving. Manufacturers focus on sustainability and performance. Recent innovations enhance durability and aesthetics. The panels are lighter yet stronger. These advancements are crucial in modern construction.

Eco-friendly materials are becoming popular. More companies emphasize recycled content in their products. This shift is beneficial for the environment. It reduces waste and lowers the carbon footprint. Consumers should look for these sustainable options.

Here’s a tip: When selecting panels, consider their fire rating. This can significantly impact safety. Also, always check warranty details to avoid future headaches. Lastly, ask about maintenance requirements. Some panels might need frequent care, while others are low-maintenance. Balancing aesthetics, performance, and sustainability is key in choosing the right product.

| Manufacturer | Year Established | Market Share (%) | Key Innovations | Sustainability Practices |

|---|---|---|---|---|

| Manufacturer A | 1995 | 25 | Nanotechnology Integration | Recycling Initiatives |

| Manufacturer B | 2000 | 30 | UV Resistance Coatings | Eco-friendly Materials |

| Manufacturer C | 1990 | 20 | Self-cleaning Surfaces | Carbon Footprint Reduction |

| Manufacturer D | 2010 | 15 | Lightweight Composite Materials | Water Conservation Techniques |

| Manufacturer E | 2015 | 10 | Enhanced Acoustic Performance | Sustainable Sourcing |

Sustainability in the aluminum composite panel industry is gaining importance. Manufacturers are increasingly focusing on eco-friendly practices. This includes using recycled materials in their panels. By incorporating recycled aluminum, they reduce the carbon footprint significantly. However, the current recycling processes are not yet perfect. Many panels still end up in landfills.

Some companies are exploring biodegradable materials to create panels. This innovation holds promise, yet it still faces challenges in durability and cost. Sustainable practices also involve energy-efficient production methods. Yet, not all manufacturers prioritize these techniques. There’s a gap between intention and implementation that needs addressing.

Investing in renewable energy sources is another area of focus. This can help reduce greenhouse gas emissions in manufacturing. However, the transition to renewable resources can be slow. Companies often struggle with the initial investment. It's crucial for the industry to find a balance between economic viability and environmental responsibility. A collective effort is needed to push for comprehensive changes. The future of sustainable aluminum composite panels relies on these developments.