Choosing the right ball screw for sale can be daunting. With numerous options available, it’s crucial to understand specific factors that can impact performance. Ball screws are vital components used in various machinery and applications. They ensure precision and efficiency in motion control systems.

When exploring ball screws for sale, consider factors like load capacity, screw diameter, and lead. These elements are essential in determining the suitability of a ball screw for your specific needs. Be mindful that not every ball screw will meet every requirement. Mistakes can be costly, so take the time to analyze your needs.

Pricing is another aspect to ponder. Cheaper options might save money upfront. However, they can lead to issues down the line. Investing in a quality ball screw can prevent future headaches. Remember, not all manufacturers provide the same level of craftsmanship. So, research thoroughly before making a decision.

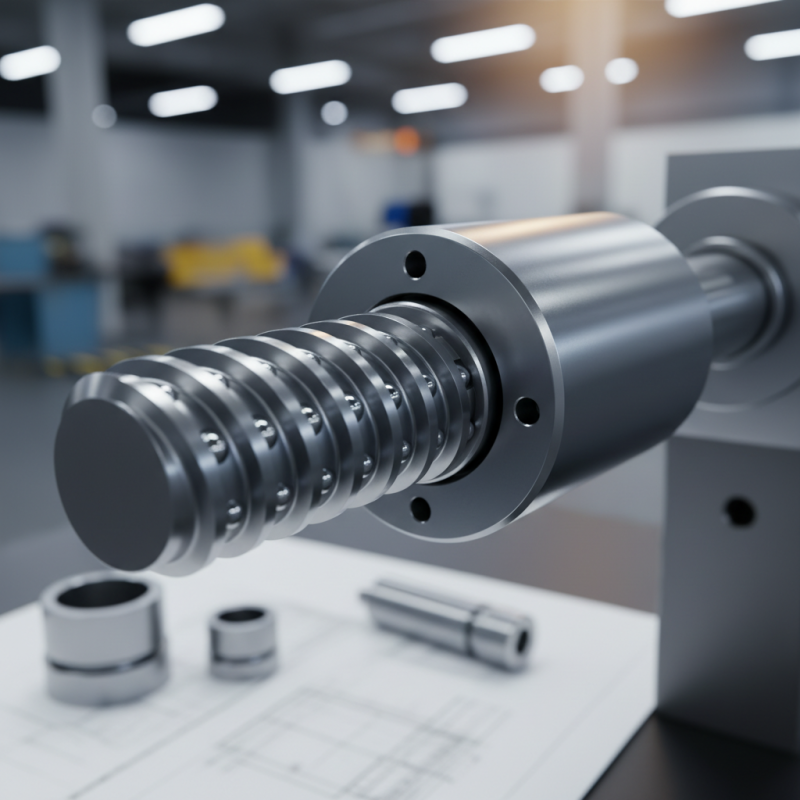

Ball screws are essential components in various machinery and automation systems. They enable linear motion with high precision and efficiency. Understanding their definition helps in choosing the right type for specific applications. Essentially, ball screws convert rotational motion into linear motion, minimizing friction and wear. This makes them ideal for CNC machines, robotics, and medical equipment.

Applications of ball screws are diverse. In manufacturing, they ensure accurate movement of tools and materials. In robotics, they provide smooth and reliable motion for robotic arms. The accuracy of a ball screw often hinges on factors like preload, diameter, and lead. Choosing the wrong specifications can lead to issues, such as increased wear or reduced efficiency.

While they are advantageous, ball screws can also be susceptible to backlash if not properly maintained. Regular inspections are crucial to ensure optimal performance. Careful attention to details like lubrication can prolong their lifespan significantly. It's important to analyze the specific requirements of your application to avoid common pitfalls.

This chart displays the performance metrics of various ball screw types, highlighting their load capacity, lead accuracy, and typical applications. The data can help in understanding the optimal choices for different industrial applications.

When selecting the best ball screws, several key factors demand attention. The material quality significantly impacts performance. Common materials include stainless steel and carbon steel, which offer different levels of durability. According to a recent industry report, ball screws made of high-strength alloys show a 30% increase in lifespan over standard options. This increase can influence long-term costs.

Another crucial aspect is the preload level. Preload affects the stiffness and accuracy of the ball screw. A higher preload can improve precision but may lead to increased friction and wear. This trade-off requires careful consideration of your application’s needs. Many users overlook this aspect, resulting in suboptimal performance and maintenance challenges.

Additionally, the efficiency rating is vital. Ball screws can achieve up to 90% efficiency, but this depends on the design and specifications. Not all ball screws deliver this performance. Choosing inefficient screws could lead to more energy consumption over time. It’s essential to weigh these factors against your operational requirements for optimal selection. Balancing performance with durability often poses challenges in decision-making. Each application might need a different approach, complicating the selection process further.

When exploring the different types of ball screws available, consider load capacity and precision. According to a recent industry report, high-load ball screws can handle up to 150% more weight than standard versions. This makes them ideal for heavy machinery and applications requiring extreme durability. However, with increased load capacity often comes higher costs.

The materials used in ball screws also greatly affect their performance. Stainless steel and alloy steel are common choices, each offering varying degrees of corrosion resistance and strength. For example, stainless steel is more resistant to oxidation but can be less stable under heavy loads. A study noted that only 25% of engineers prioritize material choice in their design phases, potentially overlooking longer-term performance aspects.

Ball screw designs vary significantly as well. Some incorporate self-lubrication systems, reducing maintenance needs. Others provide more flexibility for high-speed applications. Engineers often struggle to balance these features, especially when working with tight budgets. Even with the latest technology, some designs fall short in reliability over time. Users must weigh the trade-offs to ensure that the ball screw they choose fits their specific application.

When selecting ball screws in 2026, the focus should be on top manufacturers. Industry data indicates that ball screw demand is projected to grow by 5.2% annually. This rise reflects advancements in automation and robotics. Manufacturers are rapidly innovating to meet this increasing demand.

One major consideration is load capacity. High-quality ball screws support greater weights with lower friction. A report from the Precision Engineering Society notes that the efficiency of ball screws can reach 90%. This efficiency is crucial for applications requiring precision and speed.

Material selection also impacts performance. Steel remains a popular choice for its durability. However, some manufacturers are experimenting with composites for lighter applications. While the initial costs of these materials can be high, the long-term benefits might outweigh them.

Some key players are focusing on sustainability. They are looking at eco-friendly production methods. This reflects a shift in industry values. Not all manufacturers are adapting at the same pace, leading to a mix of innovations and shortcomings across the market. This diversity can make it challenging for buyers to choose the right supplier.

When it comes to extending the lifespan of ball screws, maintenance and care play critical roles. Regular inspection can prevent small issues from becoming serious problems. According to industry reports, proper lubrication can enhance efficiency by up to 30%. Neglecting lubrication can lead to increased friction and wear, which is avoidable with routine maintenance.

Tips: Always check lubricant levels weekly. Choose the right lubricant type for your application.

In a factory setting, dust and debris can accumulate on ball screws. This buildup can cause damage if left unaddressed. Cleaning ball screws regularly is essential. A simple wipe with a soft cloth can keep them functioning smoothly. Some studies show that clean ball screws can last 20% longer.

Tips: Use compressed air for deep cleaning. Inspect seals for wear and tear.

Keep records of maintenance activities for future reference. Regularly scheduled checks can reveal patterns in wear. Ignoring these can lead to unexpected downtime and costly repairs. Proper care is not just best practice; it’s a necessity for longevity.